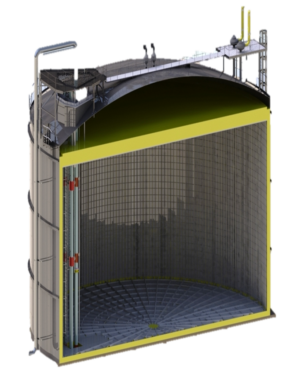

Modular GST® membrane LNG storage tank is for fast track and scalable solutions for onshore LNG terminals in remote or high labour cost areas

This concept involves prefabricating an onshore tank using GTT’s GST® membrane technology, delivering it to the end user’s site on a semi-submersible vessel, and finally completing the installation and commissioning the tank.

The modular GST® membrane technology is an adaptation of GST®technology, modified with the use of a cylindrical, low temperature steel outer tank, along with the use of a movable, patented composite steel/perlite concrete baseplate designed to make the tank light-weight (under 3,500 metric tons for a 45,000m3 tank), and transportable over remote-controlled Self-Propelled Modular Transporters (SPMT).

Main characteristics

- Low Temperature steel outer tank– SS304L or 9%Ni to act as a secondary barrier.

- Modular GST® technology

- Design adapted for transportation– Studies were carried out to validate the containment system with the base plate design.

- Capacity from 10,000 to 45,000 m3. Up to three 45,000 m3 tanks per ship.

- Schedule– 17 to 20 months for the delivery of 1 tank; 24 to 27 months for 6 tanks.

- Boil-Off Rate (BOR): 0,066%/day for a 45,000m3 with 400 mm insulation thickness considering an external T° of 19,4°C.

- Mature industrial scheme – Existing network of EPC licensees for membrane installation ready for prefabrication in China

- Well-equipped fabrication shops/yards for efficient fabrication phase.

- Better safety conditions on the prefabrication construction site.

- Optimized planning by parallelizing tank erection and site preparation.

- Adapted for harsh meteorological or political condition on the end site location

Comparing one conventional stick built 9%Ni Tank vs several smaller GST® Modular Tanks:

- Expected planning optimization: up to 8 months saving compared to stick built for the same overall net capacity.

- Expected cost saving: up to 40% for remote or with high labour cost areas.

Design in accordance with API 620/625 and revision to come of the EN 14620.

Full Containment Equivalent.

- Bigger storage capacity : +10% to +25% net LNG capacity for the same footprint, compared to a 9% Ni Full Containment system.

- Lower environmental footprint: Eco-friendly solution with -23% impact on the global environment, in comparison with 220,000 m3 standard GST tank built in China (estimation).