The storage of liquefied natural gas makes it possible to ensure an uninterrupted supply and to respond to peaks in energy consumption.

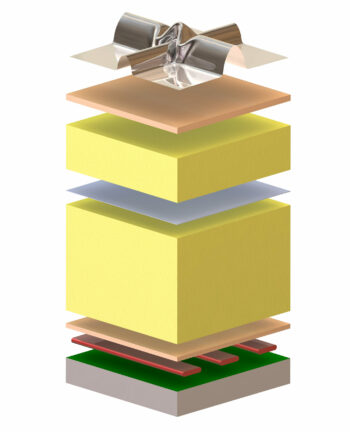

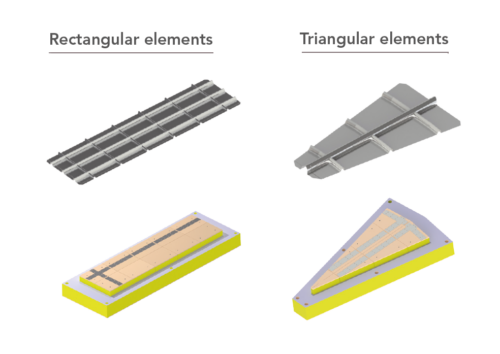

GTT has developed GST® technology, based on Mark III technology, which has proven its reliability and robustness over 60 years of existence. It is a safe and adaptable solution, whatever the tank capacity. It complies fully with international standards and meets the highest safety standards.

Tried and tested for over 50 years for the oldests ones, more than 40 onshore tanks are currently in operation.